- Overview

- Inquiry

- Related Products

|

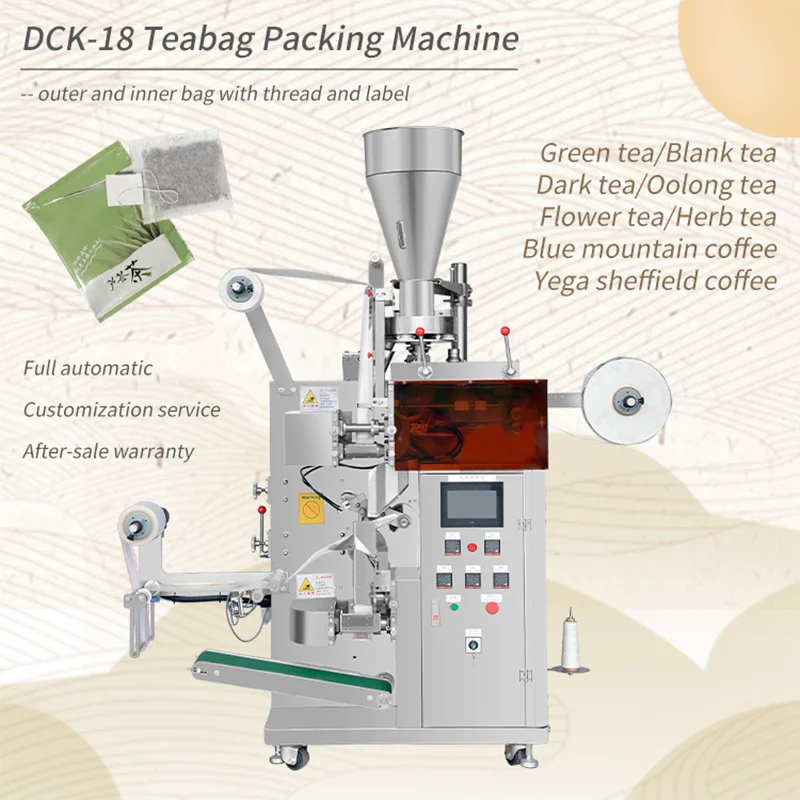

Product Model

|

DCK-18

|

|

Production Capacity

|

30-40bag/min

|

|

Thread

|

√

|

|

Label size

|

20*25/20*20mm

|

|

Inner bag size(custom)

|

L:50-75mm w:45-80mm

|

|

Outer bag size(custom)

|

L:80-120mm w:75-95mm

|

|

Voltage

|

220V 50Hz 3700W

|

|

Machine Dimensions

|

1750*740*1950mm

|

|

Machine Weight

|

450kg

|

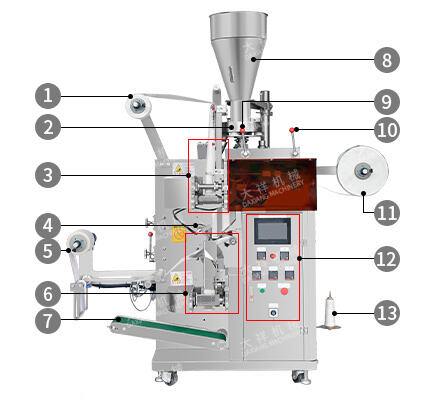

2. rotary feeder

3. sealing device (inner bag)

4. mechanical arm

5. packaging film (outer bag)

6. sealing device (outer bag)

7. belt

8. feeding storage hopper

9. feeding controller

10. cutting controller

11. label roll

12. control panel

13. thread roll (inner)

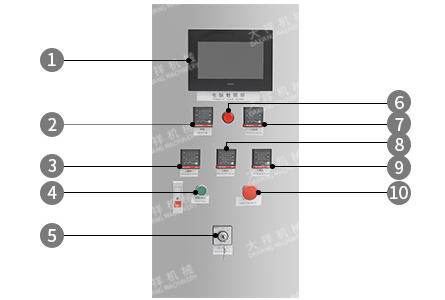

2. labeling

3. up horizontal sealing

4. start/stop

5. main switch

6. Indicator light

7. up vertical sealing

8. down vertical sealing

9. down horizontal sealing

10. urgent stop switch

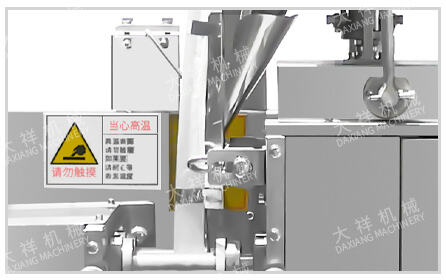

Feeding Hopper:

Big capacity hopper, made of SUS304 material. Food grade, easy to maintain.

Feeding Tray:

Measuring cup type design is to make the feeding evenly. Moreover, the feeding speed is very fast.

Former:

The size of the former can be customized. It determines the width of final product.

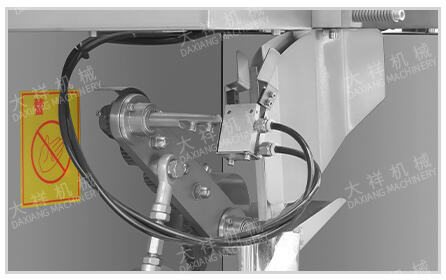

Mechanical Arm:

Move the inner bag into the outer bag flexibly. Full automatic working.

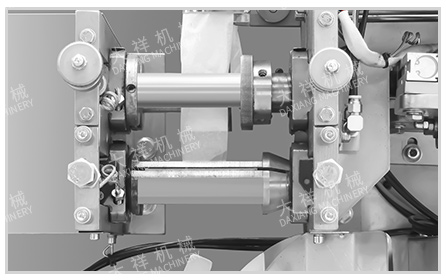

Sealing Device:

First vertically seal, then horizontally seal. Various hot sealing materials are allowed.

Conveyor:

Finished bags fall to the belt, and convey out. Durable and stable..

Cursor:

If the film is printed, the cursor help locate the track point, so each picture will be in the right position.

|

Product Model

|

DCK-10

|

DCK-11

|

DCK-18

|

|

Production Capacity

|

40-60bag/min

|

40-80bag/min

|

30-40bag/min

|

|

Thread

|

√

|

√

|

√

|

|

Label size

|

×

|

20*25/20*20mm

|

20*25/20*20mm

|

|

Inner bag size(custom)

|

L:50-75mm w:45-80mm

|

L:40-110mm w:30-80mm

|

L:50-75mm w:45-80mm

|

|

Outer bag size(custom)

|

×

|

×

|

L:80-120mm w:75-95mm

|

|

Voltage

|

220V 50Hz 1600W

|

220V 50Hz 1500W

|

220V 50Hz 3700W

|

|

Machine Dimensions

|

1100*640*1850mm

|

1790*600*1780mm

|

1750*740*1950mm

|

|

Machine Weight

|

350kg

|

350kg

|

450kg

|

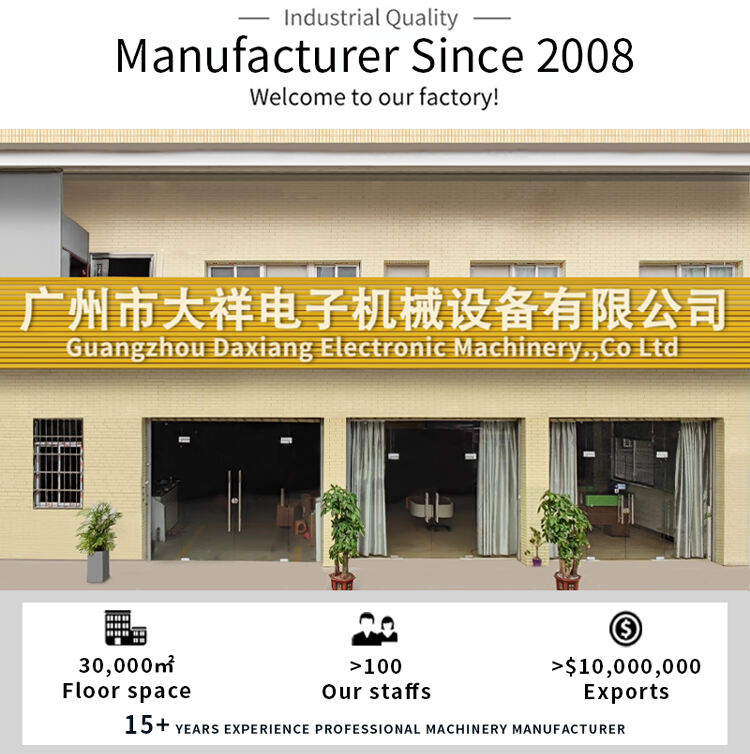

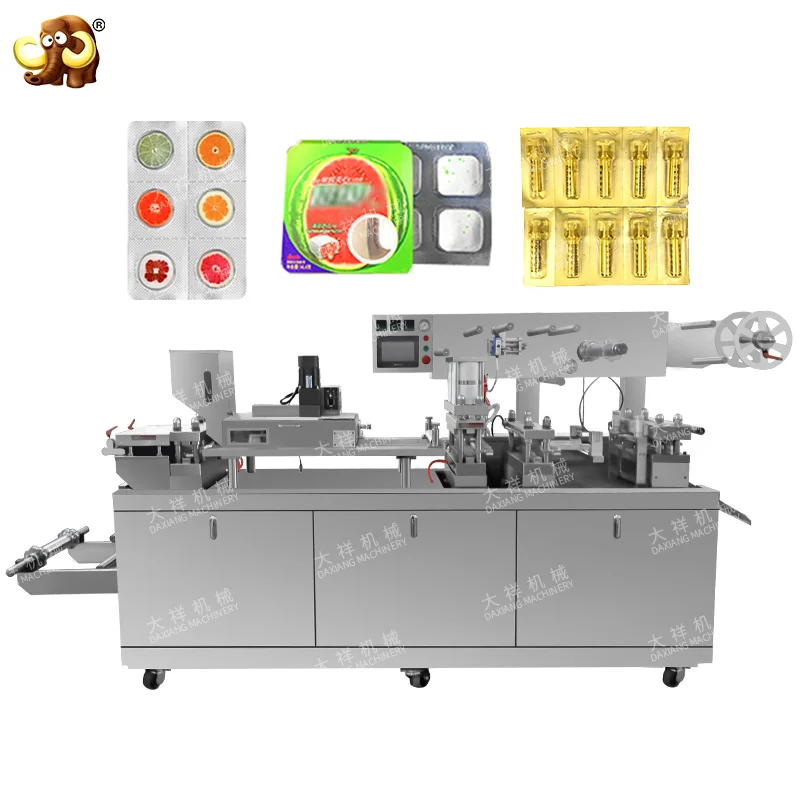

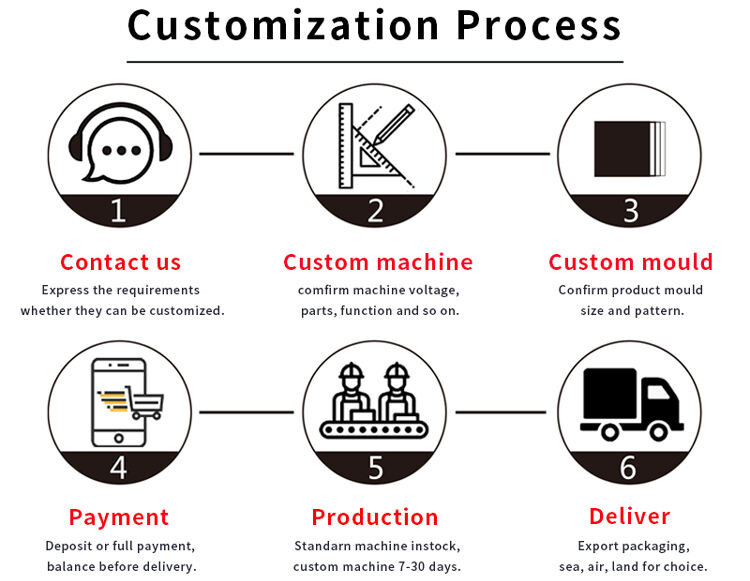

Guangzhou Daxiang Electronic Machinery Co.,Ltd is specialized in producing and selling packaging equipment and processing equipment for food, health care, chemical and cosmetics industries, including multi-functional packaging machine, blister packaging machine, vacuum packaging machine, grinding machine, sugar coating machine and so on. Our company is located in Liwan District, Guangzhou and has been doing domestic business here since 2008, in the year 2014, we started international trade for customers all over the world. Our company has various equipment and customization service that meets customers' actual needs, such as mould, voltage, plug, product appearance and so on. We have professional process and strong technical force to ensure that customers can be provided with best equipment that meets GMP requirements. All our products have CE and ISO certification.

Q1: What are your main PRODUCTS?

We produce packaging equipment and processing equipment for food, health care, chemical and cosmetics industries.

Q2: What are your PAYMENT terms?

1) T/T 2) Alibaba credit order 3) western union 4) PayPal 5) all kinds of RMB payments

Q3: How about your DELIVERY time?

Most of machines are in stock, and can be delivered within 3 days. Customized machines usually need 10-30 days to prepare.

Q4: Why do I TRUST you?

We have been producing and selling machines for over 20 years. And all our machines have passed CE and ISO certification. You can visit our factory any time you like in Guangzhou.

Q5: What is your SERVICE?

1.Customization: Most of our machines can be customized.

2.Packaging and delivery: We can pack and deliver the machine according to actual need.

3.Installation: 1) Most of our machines are ready before delivery, no need to install.

2) We provide operating videos and online support.

3) Engineers can be sent to install machines and provide training services.

Q6: What is your AFTER-SALE SERVICE?

1) One-year warranty.

2) During the warranty period, any inartificial damaged parts will be replaced free of charge.

3) After the warranty period, spare parts will be provided at a certain cost.

Daxiang

The DCK-18 High Speed Custom Service Automatic Inner and Outer Tea Bag Packing Machine is designed to meet the needs of tea packaging companies that require fast and efficient tea bag packaging solutions. This machine is built with the latest technology and comes with state-of-the-art features that ensure high-speed packaging, customized service, and robust construction.

The DCK-18 High Speed Custom Service Automatic Inner and Outer Tea Bag Packing Machine from DAXIANG can pack both inner and tea is outer simultaneously, which causes it to be highly efficient and time-saving. The inner tea bag packing roll is measured accurately and put immediately in to the bag via an auger system is feeding. The tea is exterior roll, in the other hand, is cut and created automatically into a triangular shape by the machine. The machine's unique tea is triangular design means that the tea leaves have more room to expand during brewing, providing a better tea consumption experience.

Features a interface is user-friendly simplifies the packaging procedure, providing a personalized interface that allows customers to modify tea bags according to their preferences. With the touch screen, customers can program the size easily, weight, and model of the tea bag to meet their requirements.

Made with durability in mind, this features a construction is robust with most parts made of high-quality stainless steel that prolongs its lifespan and reduces maintenance costs. The machine has a noise is low and is easy to operate, making it perfect for tea packaging companies looking to enhance their packaging process's quality and efficiency.

Another feature is its high-speed performance. It can pack up to 200-250 bags per minute, with respect to the tea material and size. This amazing speed helps companies save time and increase production capacity while maintaining packaging quality is good.

Choose Daxiang’s DCK-18 High Speed Custom Service Automatic Inner and Outer Tea Bag Packing Machine , and you won't regret it.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LO

LO