- Overview

- Inquiry

- Related Products

|

Product Model

|

DXB-100J

|

|

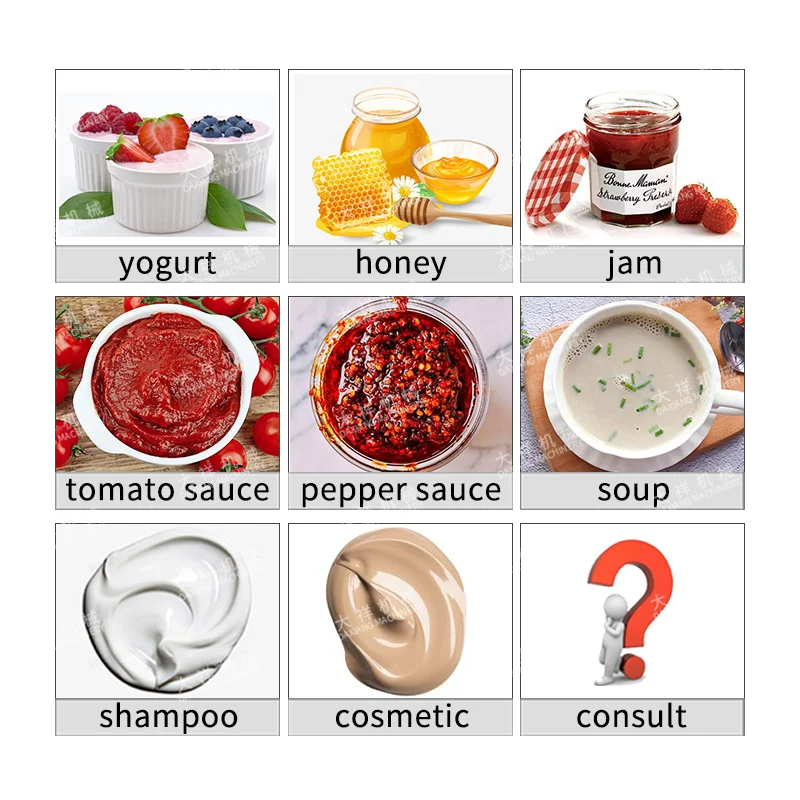

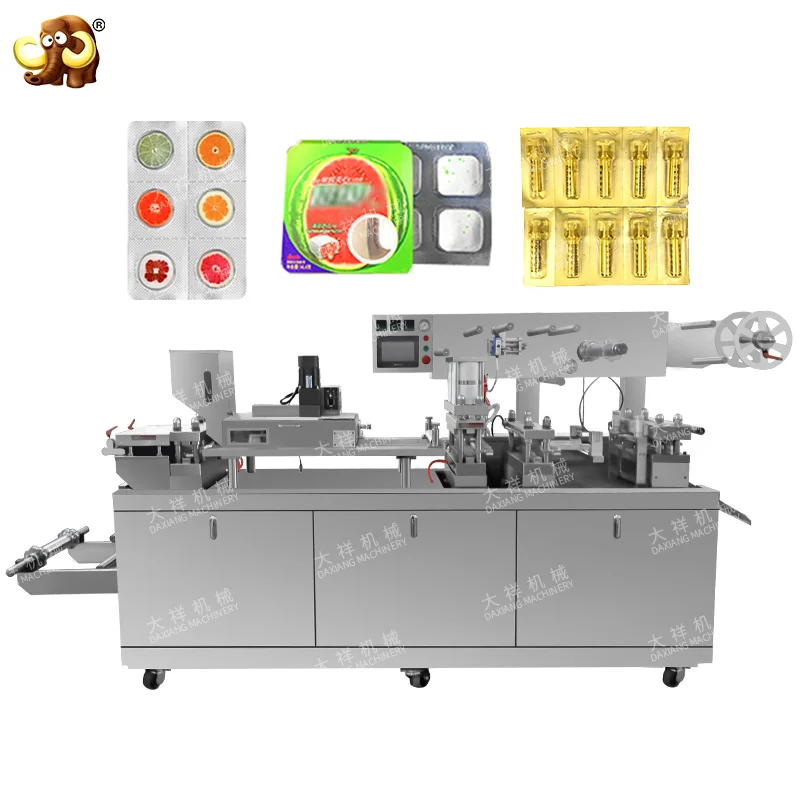

Application

|

Liquid/Paste

|

|

Production Capacity

|

30-60bag/min

|

|

Packaging Weight

|

1-100g/3-100ml

|

|

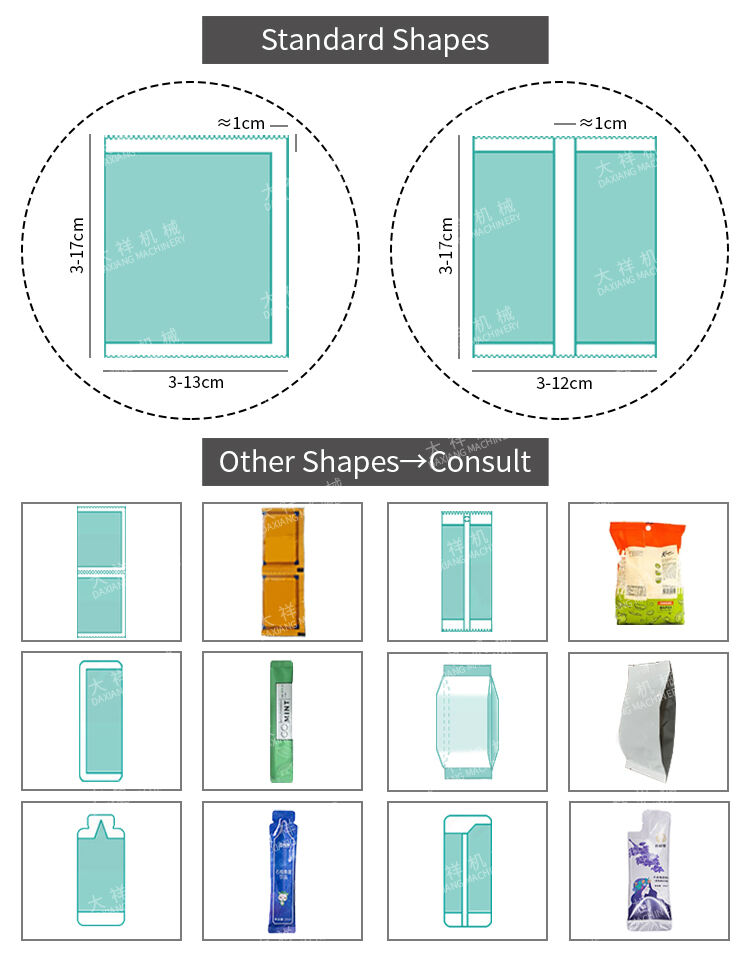

Packaging Length

|

3-17cm

|

|

Packaging Width

|

3-13cm

|

|

Voltage

|

220V 50Hz 1.4kW

|

|

Machine Weight

|

250kg

|

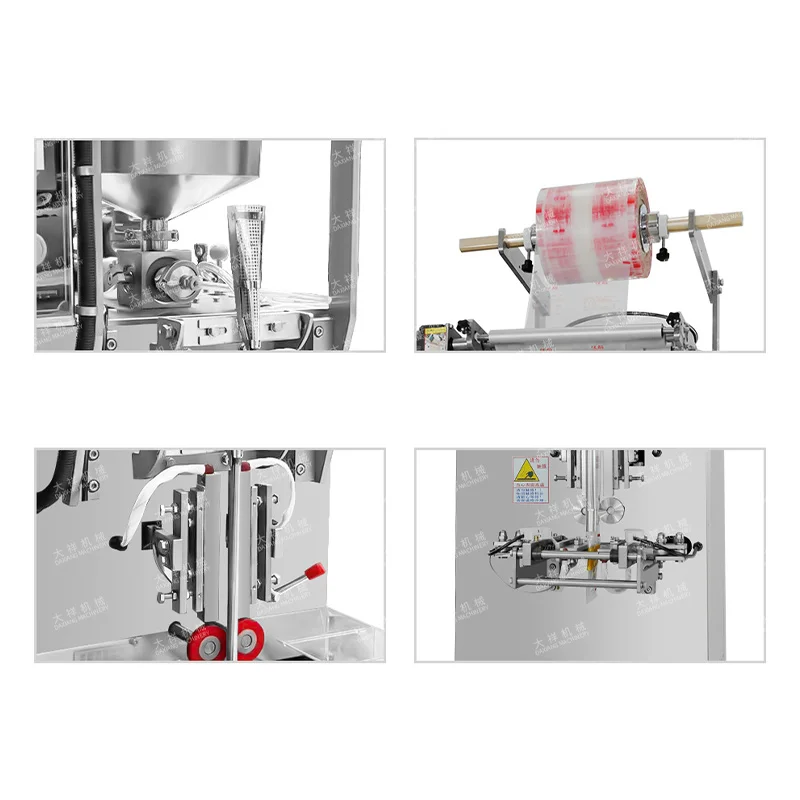

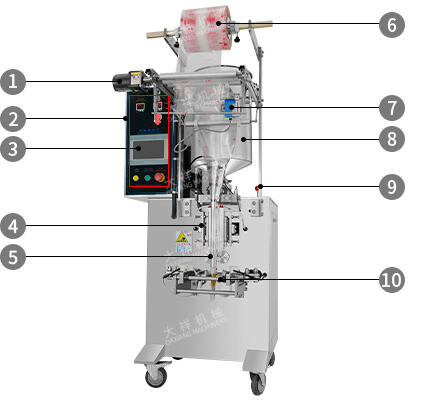

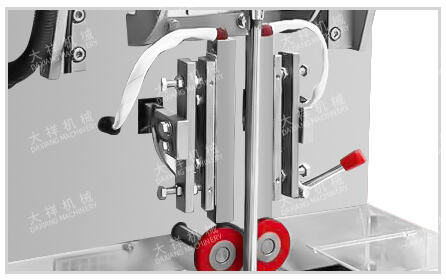

2. control panel

3. touch screen

4. vertical heat-seal

5. former

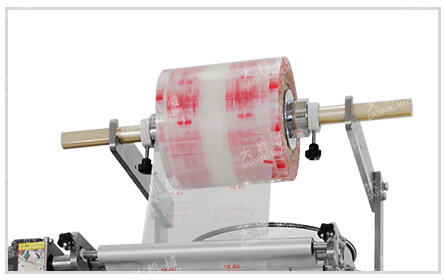

6. packaging film

7. cursor

8. feeding storage hopper

9. feeding controller

10. horizontal heat-seal

2. touch screen

3. step

4. horizontal temp control

5. start/stop

6. emergency stop

Packaging Film:

Suitable for various heat sealing packaging film, such as filter paper, nonwovens, composite film, aluminum film, printed film and so on.

Feeding Hopper:

Big capacity hopper, made of SUS304 material. Food grade, easy to maintain.

Former:

The size of the former can be customized. It determines the width of final product.

Vertical Heat-seal:

Heat seal the side of the pouch automatically. Temperature can be adjusted according to different materials.

Horizontal Heat-seal

Heat seal the top and bottom side of the pouch automatically. Temperature can be adjusted according to different materials. Then cut pouches one by one.

Cursor:

If the film is blank, no need for cursor. If the film is printed, the cursor help locate the track point, so each picture will be

in the right position.

|

Machine Model

|

DXB-100J

|

|

Application

|

Liquid & Paste

|

|

Production Capacity

|

30-60bag/min

|

|

Packaging Weight

|

1-100g/3-100ml

|

|

Packaging Length

|

3-17cm

|

|

Packaging Width

|

3-13cm

|

|

Packaging Accuracy

|

1g

|

|

Machine Voltage

|

220V 50Hz 1.4kW

|

|

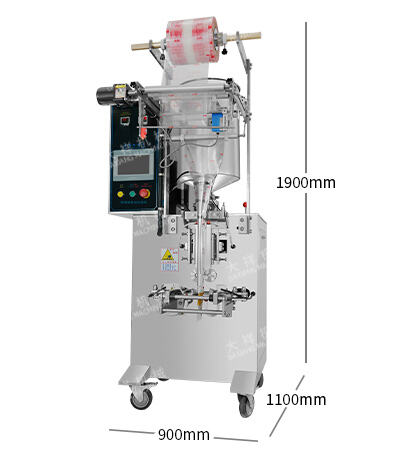

Machine Dimensions

|

900*1100*1900mm

|

|

Machine Weight

|

250kg

|

|

Optional

|

Coder

|

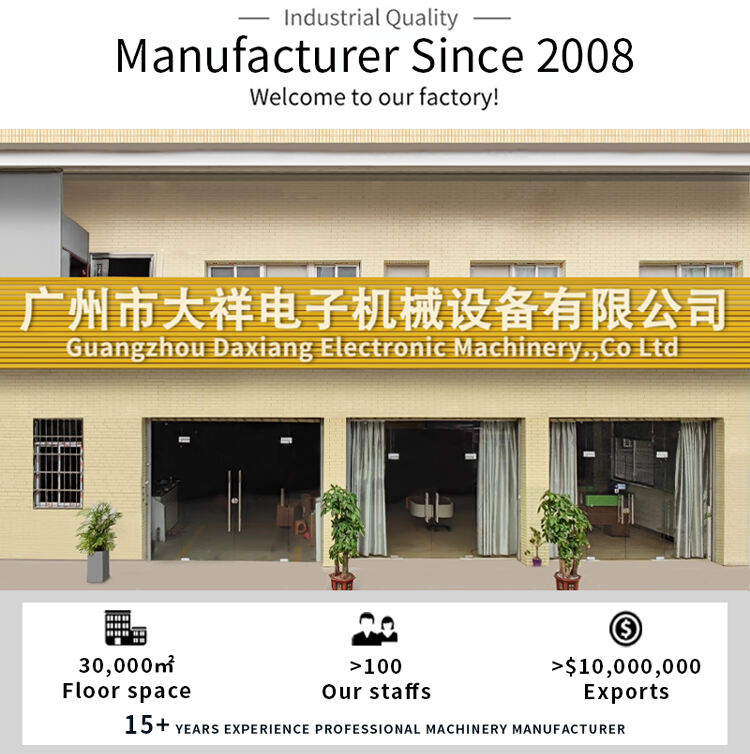

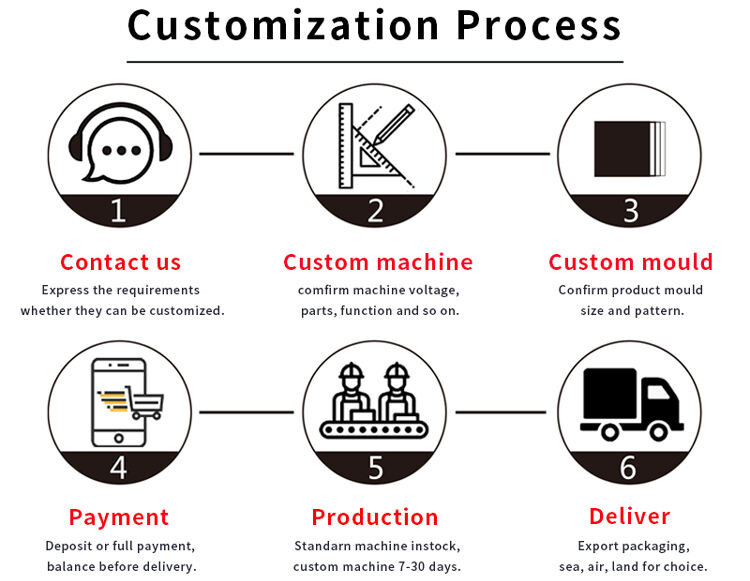

Guangzhou Daxiang Electronic Machinery Co.,Ltd is specialized in producing and selling packaging equipment and processing equipment for food, health care, chemical and cosmetics industries, including multi-functional packaging machine, blister packaging machine, vacuum packaging machine, grinding machine, sugar coating machine and so on. Our company is located in Liwan District, Guangzhou and has been doing domestic business here since 2008, in the year 2014, we started international trade for customers all over the world. Our company has various equipment and customization service that meets customers' actual needs, such as mould, voltage, plug, product appearance and so on. We have professional process and strong technical force to ensure that customers can be provided with best equipment that meets GMP requirements. All our products have CE and ISO certification.

We produce packaging equipment and processing equipment for food, health care, chemical and cosmetics industries.

Q2: What is your PAYMENT terms?

1) T/T 2) alibaba credit order 3) western union 4) paypal 5) all kinds of RMB payments

Q3: How about your DELIVERY time?

Most of machines are in stock, and can be delivered within 3 days. Customized machines usually need 10-30 days to prepare.

Q4: Why do I TRUST you?

We have been producing and selling machines for over 20 years. And all our machines have passed CE and ISO certification. You can visit our factory any time you like in Guangzhou.

Q5: What is your SERVICE?

1.Customization: Most of our machines can be customized.

2.Packaging and delivery: We can pack and deliver the machine according to actual need.

3.Installation: 1) Most of our machines are ready before delivery, no need to install.

2) We provide operating videos and online support.

3) Engineers can be sent to install machines and provide training services.

Q6: What is your AFTER-SALE SERVICE?

1) One-year warranty.

2) During the warranty period, any unartificial damaged parts will be replaced free of charge.

3) After the warranty period, spare parts will be provided at a certain cost.

DAXIANG

Presenting the DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine, the latest innovation from the trusted and innovative brand. This advanced machine is designed to offer efficient and reliable packing of one's favorite foods such as jam, ketchup, chili sauce, and peanut butter, in synthetic bags.

This DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine boasts of a fast rate mechanism that allows it to finish off to 60 bags each full minute, rendering it ideal for used in high amount production facilities. The gear's jam, ketchup, chili sauce, and peanut butter compatibility means it is a very versatile machine that may effortlessly fulfill the diverse packing needs of varied meals manufacturers, thus making.

One of the many benefits of the DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine is its accuracy. Due to its advanced servo motor system, it might precisely determine and dispense the needed amount of product into the plastic bags, ensuring constant levels that are filling.

Furthermore, this DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine has high-end sensors that can detect and effortlessly resolve any errors which could arise during the packing process. This feature provides a hassle-free and seamless operation of the machine, hence boosting overall productivity.

The DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine also is sold with a user-friendly control that enables the operator to set the specified parameters, adjust pack sizes, and monitor the overall operation with all the machines. This feature causes it to be effortless for operators to adapt to the product's operation, reducing downtime, and enhancing efficiency.

The DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine is also designed to optimize the utilization of space, thanks to its design and ergonomic compact. This feature causes it to be an ideal choice, limited space is available, and storage area is important.

The DXB-100J Fast Speed Auto Jam Ketchup Chilly Sauce Peanut Butter Plastic Bag Packing Machine is built to provide long-term dependability solution to its users. DAXIANG utilizes top-notch materials and components with its construction, making certain the product can withstand harsh production while enduring the test of time.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LO

LO