DZD-220JB Hot Sales Paste Honey Stick Oil Jam Ketchup Sauce Viscous Liquid Automatic Sachet Packaging Machine

- Overview

- Inquiry

- Related Products

DAXIANG

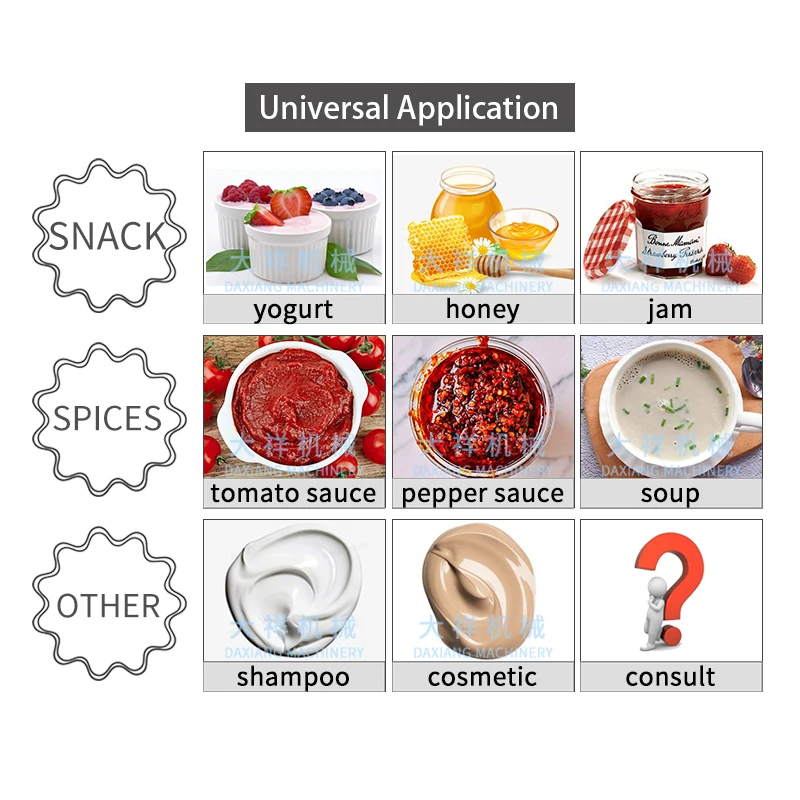

Launching the DZD-220JB Hot Sales Paste Honey Stick Oil Jam Ketchup Sauce Viscous Liquid Automatic Sachet Packaging Machine, the answer clear is ultimate your packaging needs. This automated sachet packaging device is here to simply help whether you need to bundle honey, ketchup, oil, jam, or other fluid viscous. Having its efficient design and user-friendly software, you will bundle simplicity and accuracy to your products or services.

The DZD-220JB Hot Sales Paste Honey Stick Oil Jam Ketchup Sauce Viscous Liquid Automatic Sachet Packaging Machine from DAXIANG may be the addition perfect any food processing facility, bakery, or restaurant. It provides a control sensible that allows one to add the packaging rate, heat, and sealing time according to your product’s packaging and viscosity demands. These devices are with the capability of filling and packing as much as 50 sachets each minute, helping you save work and time expenses.

The apparatus is created specifically to cope with fluids being viscous as honey, oil, jam, and ketchup. Its piston filler exclusive that the fluid is accurately dispensed towards the sachets without having any overflow or mess. The apparatus and cutting sealing that the sachets are completely sealed, preventing any leakages or spillage during transportation or storage area.

The DZD-220JB Hot Sales Paste Honey Stick Oil Jam Ketchup Sauce Viscous Liquid Automatic Sachet Packaging Machine is not only efficient, but it is additionally user-friendly. Its display touchscreen displays you to effortlessly put up and run these devices with only several presses, no experience prior. Its lightweight and design sturdy it super easy to put any work area on and to maneuver around whenever needed. It is quite simple to wash, saving you upkeep and time expenses.

The gear is made with top-quality materials and components that will endure. It's sustained by a dependable guarantee and exemplary customer care, ensuring you will need as soon you have most of the help as you buy the equipment.

|

Product Model

|

DZD-220JB (back seal)

|

|

Application

|

Liquid/Paste

|

|

Production Capacity

|

10-30bag/min

|

|

Packaging Weight (water)

|

10-200g/10-500g/10-1000g

|

|

Packaging Length

|

1-15cm/1-19cm/1-26cm

|

|

Packaging Width

|

2.25-10cm (Film 6-22cm)

6-15cm (Film 14-32cm)

9-20cm (Film 20-42cm)

|

|

Voltage

|

220V 50Hz 450W

|

|

Machine Weight

|

80kg

|

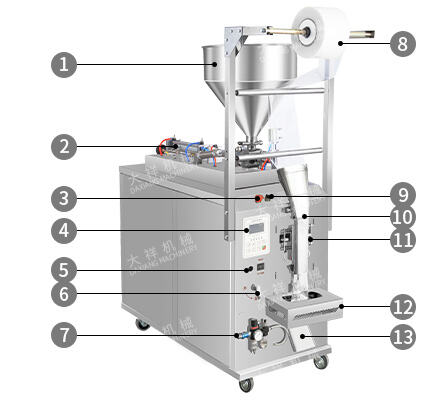

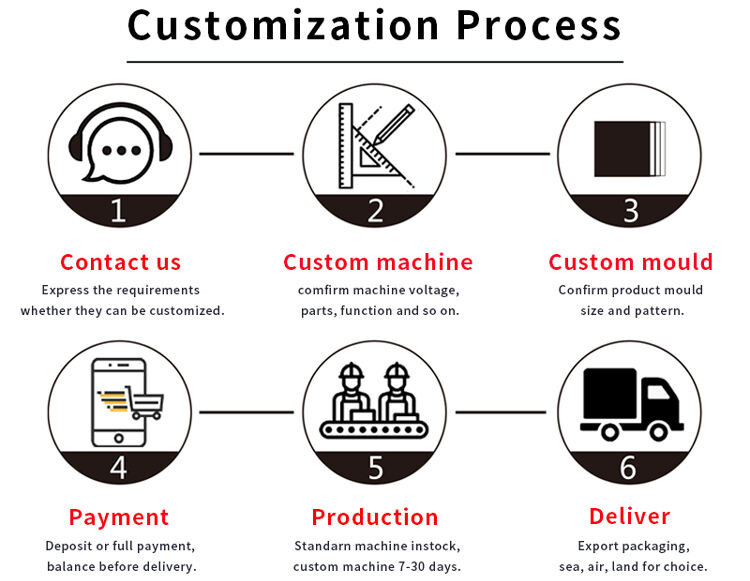

Diagram

2. air cylinder

3. emergency stop

4. control panel

5. main switch

6. sealing locker

7. barometer

8. packaging film

9. washing switch

10. former

11. vertical heat-seal

12. horizontal heat-seal

13. output

Feeding Hopper:

Stainless steel material. Smooth surface, easy to clean. Custom service include bigger volume hopper, heating function, stirring device and so on.

Subpackaging Adjustor:

Each pouch of packaging volume can be adjusted by controlling the adjuster. Range can be customized 5-50ml, 10-200ml, 20-500ml, 10-1000ml and so on.

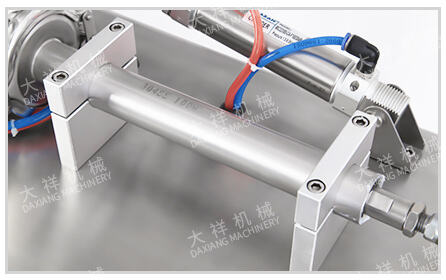

Air Cylinder:

Brand air cylinder, good quality and durable. Dismountable parts make the cleaning easy.

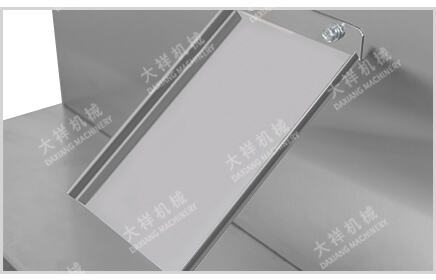

Former:

The size of the former can be customized. It determines the width of final product.

Vertical Heat-seal:

Heat seal the side of the pouch automatically. Temperature can be adjusted according to different materials.

Horizontal Heat-seal

Heat seal the top and bottom side of the pouch automatically. Temperature can be adjusted according to different materials. Then cut pouches one by one.

Output:

The whole machine is made of stainless steel. Food grade, smooth and durable. Easy to collect finished product.

Control Panel:

Adjust the volume of the liquid and the length of pouch. Control the temperature of sealing according to different packaging film. Automatic and accurate.

|

Product Model

|

DZD-220JB (3 side seal)

|

DZD-220JB (back seal)

|

|

Application

|

Liquid/Paste

|

Liquid/Paste

|

|

Production Capacity

|

10-30bag/min

|

10-30bag/min

|

|

Packaging Weight (water)

|

10-200g

|

10-200g/10-500g/10-1000g

|

|

Packaging Length

|

1-15cm

|

1-15cm/1-19cm/1-26cm

|

|

Packaging Width

|

3-10cm (Film 6-20cm)

|

2.25-10cm (Film 6-22cm)

6-15cm (Film 14-32cm)

9-20cm (Film 20-42cm)

|

|

Voltage

|

220V 50Hz 450W

|

220V 50Hz 450W

|

|

Machine Dimensions

|

540*1080*1640mm

|

540*1080*1640mm

|

|

Machine Weight

|

80kg

|

80kg

|

|

Optional

|

Cursor/Coder

|

Cursor/Coder

|

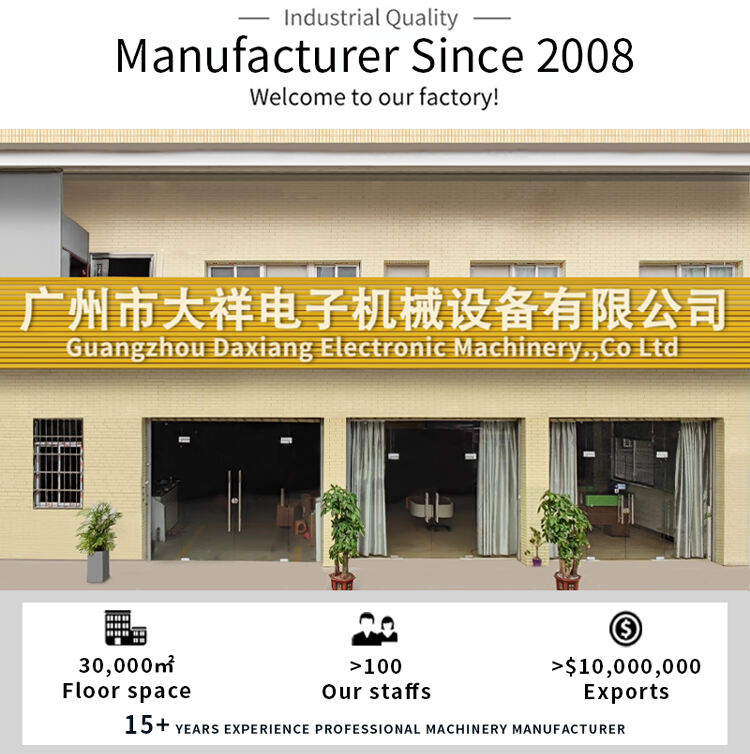

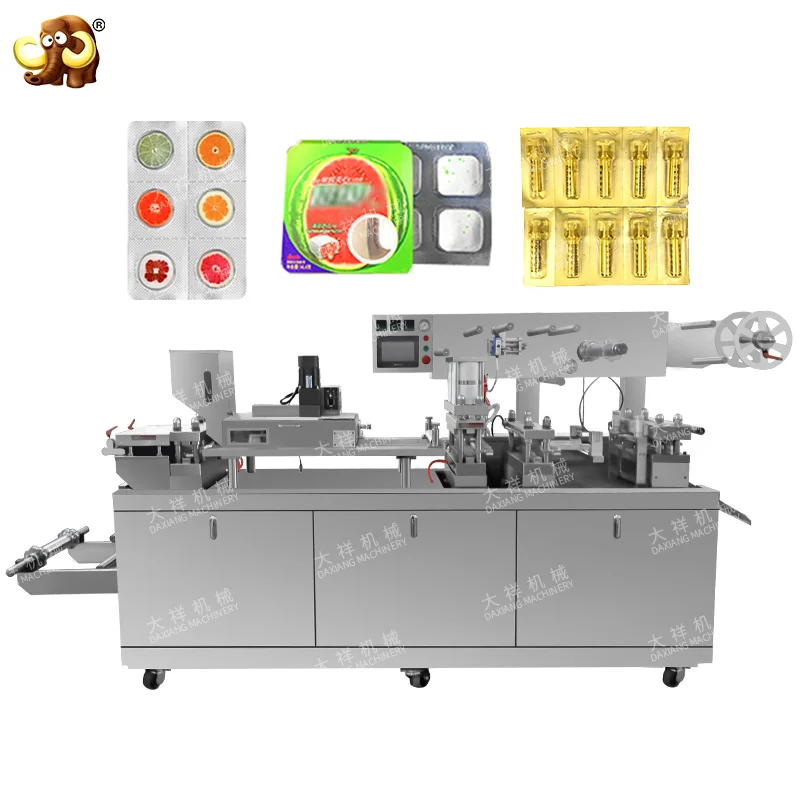

Guangzhou Daxiang Electronic Machinery Co.,Ltd is specialized in producing and selling packaging equipment and processing equipment for food, health care, chemical and cosmetics industries, including multi-functional packaging machine, blister packaging machine, vacuum packaging machine, grinding machine, sugar coating machine and so on. Our company is located in Liwan District, Guangzhou and has been doing domestic business here since 2008, in the year 2014, we started international trade for customers all over the world. Our company has various equipment and customization service that meets customers' actual needs, such as mould, voltage, plug, product appearance and so on. We have professional process and strong technical force to ensure that customers can be provided with best equipment that meets GMP requirements. All our products have CE and ISO certification.

We produce packaging equipment and processing equipment for food, health care, chemical and cosmetics industries.

Q2: What is your PAYMENT terms?

1) T/T 2) alibaba credit order 3) western union 4) paypal 5) all kinds of RMB payments

Q3: How about your DELIVERY time?

Most of machines are in stock, and can be delivered within 3 days. Customized machines usually need 10-30 days to prepare.

Q4: Why do I TRUST you?

We have been producing and selling machines for over 20 years. And all our machines have passed CE and ISO certification. You can visit our factory any time you like in Guangzhou.

Q5: What is your SERVICE?

1.Customization: Most of our machines can be customized.

2.Packaging and delivery: We can pack and deliver the machine according to actual need.

3.Installation: 1) Most of our machines are ready before delivery, no need to install.

2) We provide operating videos and online support.

3) Engineers can be sent to install machines and provide training services.

Q6: What is your AFTER-SALE SERVICE?

1) One-year warranty.

2) During the warranty period, any unartificial damaged parts will be replaced free of charge.

3) After the warranty period, spare parts will be provided at a certain cost.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LO

LO